Product Application | Securing New Orders in the Steel Industry: The T-M series modules facilitate the intelligent upgrade of bar and wire rolling mills in large domestic steel enterprises

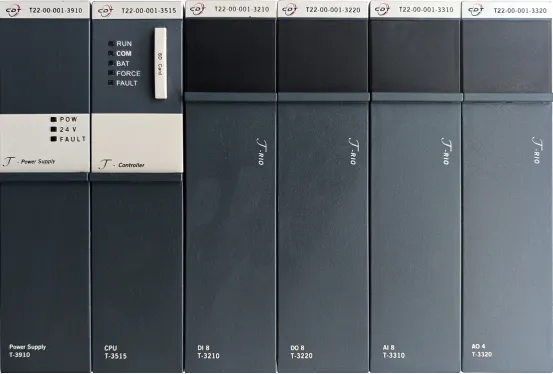

Recently, the high-speed T-M remote IO module of Tianjin Changdatong Technology Co., Ltd. has been successfully applied to the upgrade project of the automatic control system of the bar and wire rolling mill of a large domestic steel enterprise. This cooperation not only highlights Changdatong Technology's core competitiveness in the high-end equipment field of the metallurgical industry, but also sets a new benchmark for the large-scale application of domestic industrial control products in complex scenarios.

Deeply engaged in the metallurgical industry, its technical strength has been recognized

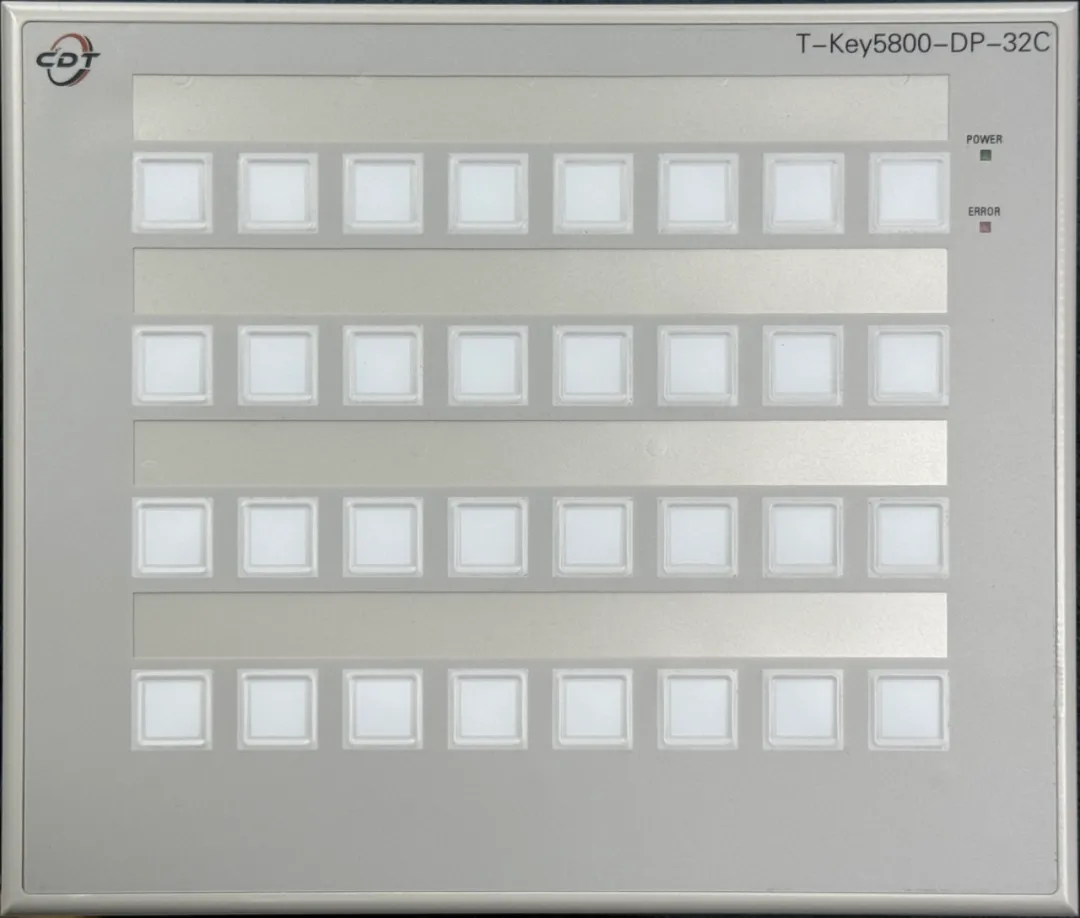

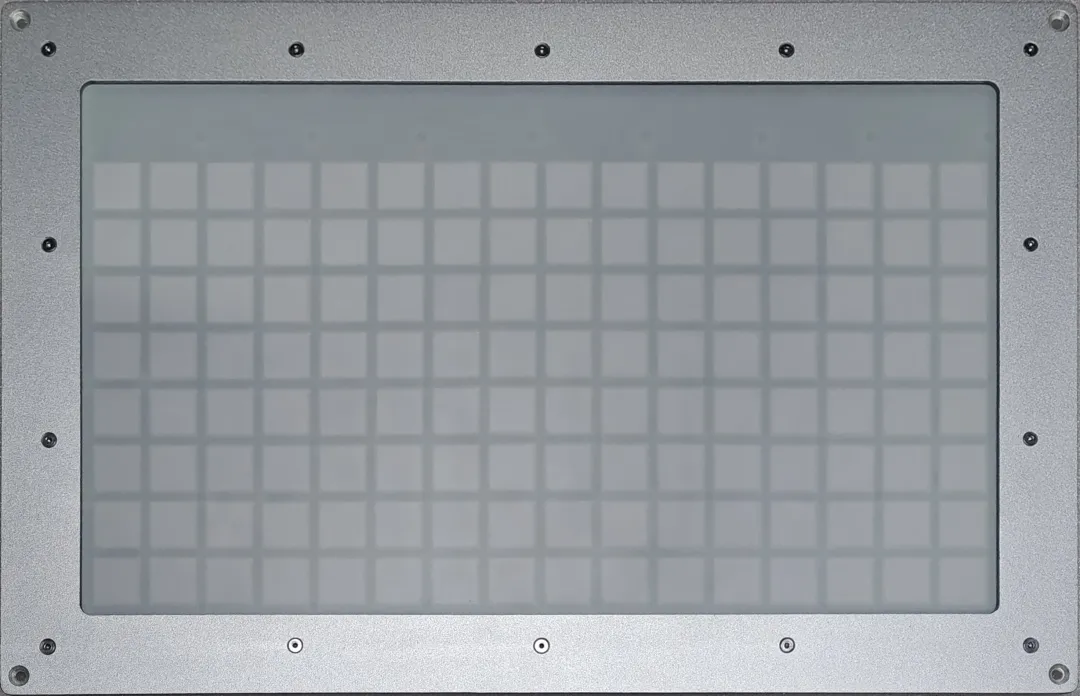

As the first innovative enterprise in China to achieve large-scale application of independently controlled products in the core process section of metallurgy, Changdatong Technology has always been committed to providing highly reliable and cost-effective solutions for industrial automation. In this project, the T-M series modules, with their high-speed response speed technology and adaptability to harsh environments, met the customers' strict requirements for high-speed response, stable operation and long-term reliability of the rolling mill system.

The core advantage of the T-M series: Tailor-made for the steel industry

In the high-precision and high-load application scenario of the bar and wire rolling mill, the T-M series modules demonstrate their unique technical advantages:

High-speed real-time control: Based on the independently developed intelligent control architecture, it achieves rapid response capabilities, ensuring the efficient synchronization and precise execution of rolling mill process data.

Passive backplane and hot-swapable design: Supports power-on maintenance of modules, significantly reduces production line downtime, and enhances system availability;

All-scenario adaptability: Relying on multiple anti-interference technologies and industrial-grade environmental adaptability optimization, combined with fanless and wide-temperature-range operation characteristics, it can easily handle high-temperature and high-dust steel rolling sites.

Flexible expansion capability: Supports multi-slot backplane configuration and distributed IO architecture, meeting the flexible expansion and future intelligent upgrade requirements of customers' production lines.

Empower intelligent manufacturing and promote industry upgrading

As a key equipment in steel production, the automation system of the bar and wire rolling mill needs to take into account high speed, high reliability and easy maintenance. The T-M series modules, through the distributed IO architecture and PROFINET, achieve seamless integration and efficient processing of data in each process section of the rolling mill, assisting customers in building intelligent and digital production line control systems. This cooperation not only enhanced the production efficiency and product quality of the client, but also verified the substitution ability of domestic industrial control systems in the high-end manufacturing field.

Continuous innovation, serving the world

Taking this order as an opportunity, Changdatong Technology will continue to deepen its R&D investment in fields such as metallurgy and energy, and promote the advancement of domestic industrial control products towards high-end and internationalization. The company has always adhered to the market positioning of "complete autonomy and the best cost performance", and is committed to empowering the global industrial intelligent transformation with innovative technologies.

Tianjin Changdatong Technology Co., LTD

Please first Loginlater ~