Talk about the application of energy management system in steel enterprises

In the next 20 years or so, China will enter the mid-industrialization development stage, as an important engineering structural material in the manufacturing and construction industry, the total demand for steel will further increase. The iron and steel industry is the basic industry of the national economy and occupies an important position in China's economic life. The steel industry is a typical resource-consuming industry, with huge consumption of raw materials, fuels and energy power. The previous energy-saving management methods were mainly to account for power costs, drip and run management, index assessment, etc., these methods have achieved certain results, but in order to improve the potential of management methods and meet the needs of the market economy, a new management platform should be established to supervise energy use, save energy and reduce consumption, and reduce economic costs. With this goal in mind, after repeated discussions and investigations, combined with modern scientific management methods, and relying on advanced software computing, an energy management system with monitoring and management functions such as energy planning, energy performance, energy cost, energy forecasting, energy balance, energy dispatch, energy equipment and energy quality was designed.

Energy is the lifeblood of enterprises, and how to use energy effectively has been elevated to a vital strategic position. Especially for large and medium-sized metallurgical enterprises, the construction of informatization, the establishment of an information communication mechanism between energy supply and demand, through "comprehensive resource planning", to achieve "scientific allocation of energy" is possible. There are more than 4,000 data collection nodes in the energy management system of large steel enterprises, covering gas, oxygen, nitrogen, industrial water, steam, compressed air and other media. The automation, informatization and intelligence of energy management, online measurement, automatic collection, fault diagnosis and analysis, and energy balance prediction of energy media can effectively reduce and eliminate energy waste. Therefore, it is important to build an energy management system to achieve rational and efficient energy utilization.

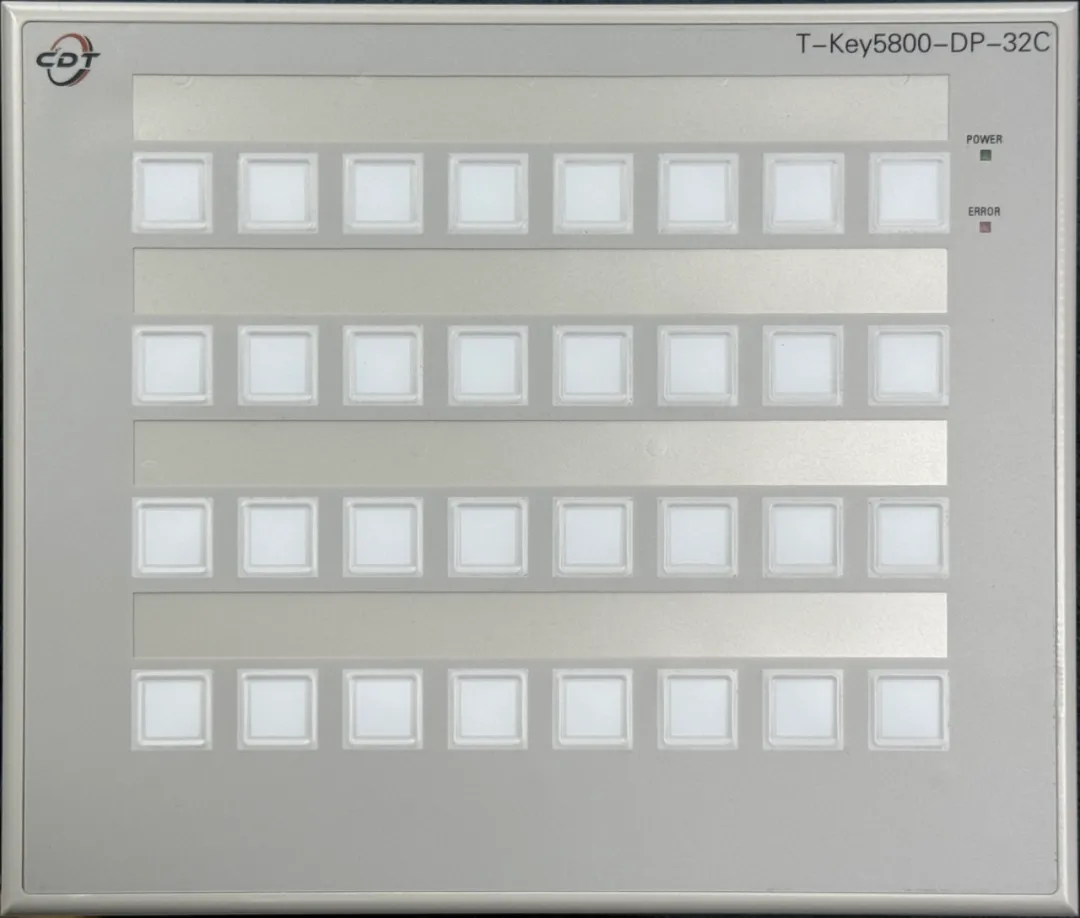

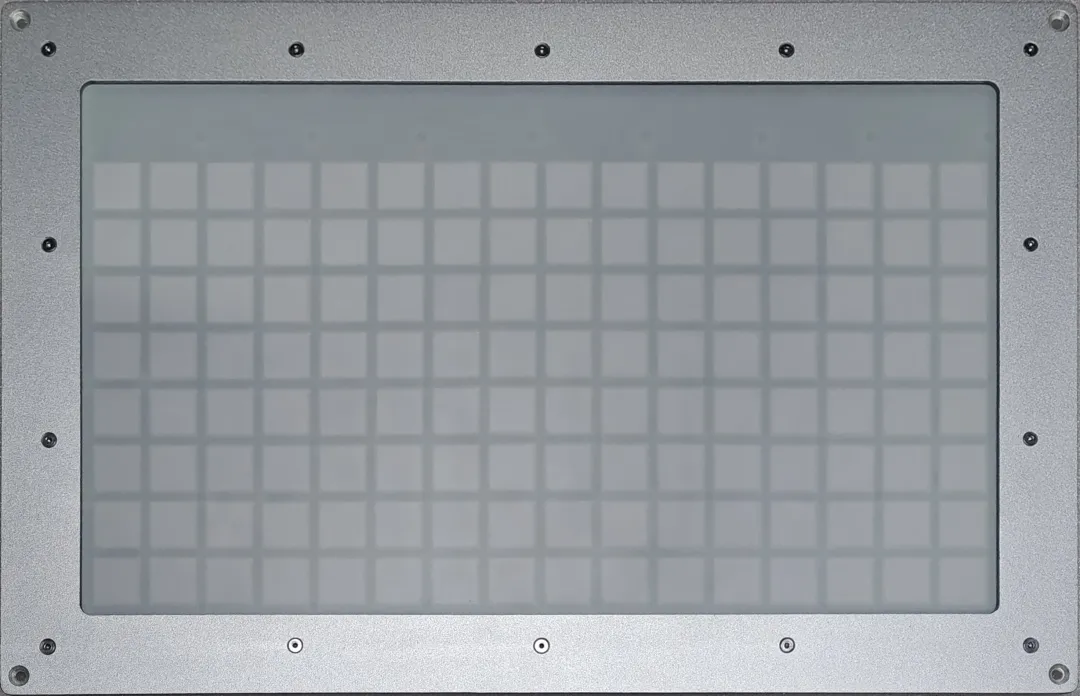

The basic structure of the information system construction of large-scale metallurgical enterprises has been formed, and according to the management model, the system level is clear and clear, and the function sharing is more reasonable. As shown in Figure 1, system development and construction cannot be limited to the IT department programming and development functions, so before the development of information systems, clarify the organizational structure and business processes of management.

Please first Loginlater ~