"Chang" talk about the difference between soft PLC and hard PLC

In today's industrial automation field, programmable logic controllers (PLCS) play a crucial role as the core brain of industrial equipment. However, with the continuous development of technology, the dispute between the traditional hard PLC and the emerging soft PLC has also intensified. Tianjin Changdatong Technology Co., LTD., as a collection of research and development, production, OEM, sales, service as one of the innovative technology-based enterprises, with its profound technical accumulation in the field of PLC, is leading the new future of industrial control with innovative technology.

Hard PLC, with its stable and reliable performance, has long been the first choice in the field of industrial automation. They typically include hardware components such as processors, input/output modules, and power supplies that are specifically designed for industrial environments to ensure their stable operation in harsh conditions. The advantage of hard PLCS is their high stability and durability, which is especially suitable for industrial scenarios where downtime requirements are extremely stringent.

However, with the rapid development of information technology, soft PLC began to emerge. Soft PLC is a kind of PC-based control software, which realizes the function of PLC through software and runs on standard PC hardware. The advantages of soft PLC are its high degree of flexibility, easy programming and maintenance, and relatively low cost. IT can use a more general programming environment, such as the programming languages supported by the IEC 61131-3 standard, which makes it easier to integrate into existing IT infrastructure. In addition, soft PLCS can easily increase processing power or I/O points according to actual needs, just by configuring the software or upgrading the hardware.

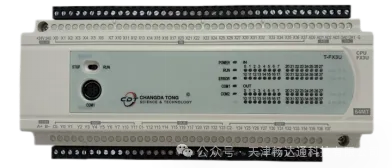

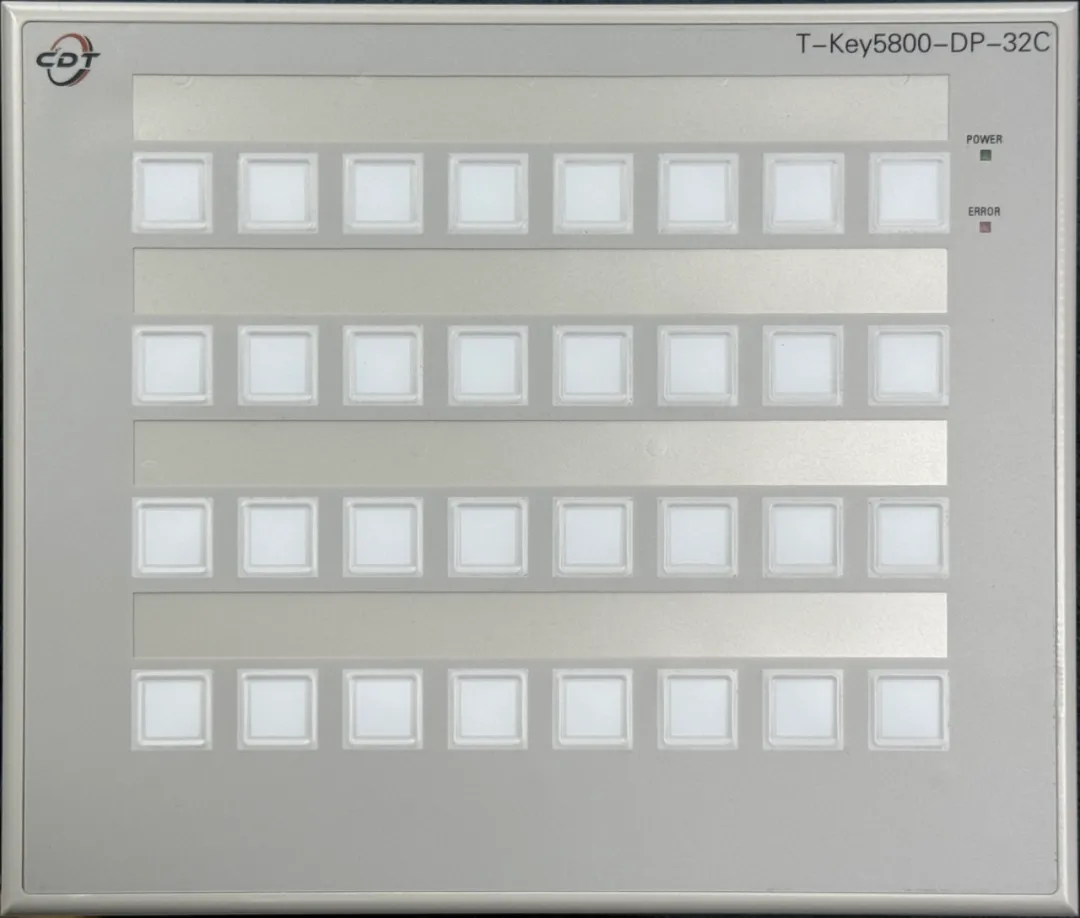

Tianjin Changdatong Technology Co., Ltd. launched its PLC FX3U series. PLC FX3U supports GX Developer and GX Works2 software programming, analog processing, communication interface, interrupt function, password setting and other aspects are excellent, especially suitable for industrial automation applications that require high control accuracy and stability.

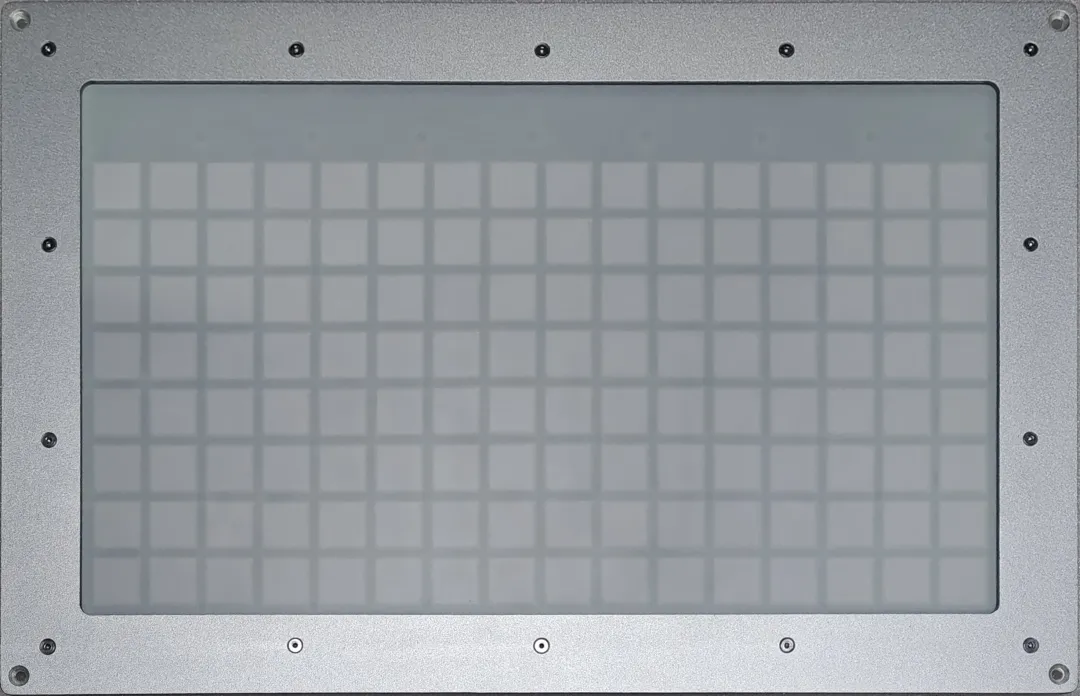

In addition, Tianjin Changdatong Technology Co., Ltd. also launched the T-IPC-3517 series of high-performance embedded industrial computer, these products not only have powerful computing power, but also support a variety of communication interfaces and expansion slots, which can be easily integrated into a variety of industrial automation systems. They are not only suitable for traditional hard PLC application scenarios, but also can be used as the hardware basis of soft PLC, providing a more flexible and efficient solution for industrial control.

In the field of industrial automation in the future, the battle between soft PLC and hard PLC will continue. However, Tianjin Changdatong Technology Co., Ltd. has taken the lead in this competition with its profound technology accumulation and innovative spirit. The company will continue to promote the innovation of industrial control technology and contribute more to the development of industrial automation.

Please first Loginlater ~